Dental Handpieces: Complete Guide to High-Speed and Low-Speed Handpiece Systems

Modern dentistry relies heavily on precision instruments that deliver consistent performance across a wide variety of procedures. Among these essential tools, dental handpieces stand as the cornerstone of efficient patient care, enabling practitioners to perform everything from routine cleanings to complex restorative work with exceptional accuracy and control.

Whether you’re establishing a new practise, upgrading existing equipment, or simply seeking to optimise your current handpiece selection, understanding the nuances of these sophisticated instruments is crucial for delivering superior patient care while maintaining operational efficiency. This comprehensive guide explores the technical specifications, clinical applications, and selection criteria that define today’s advanced handpiece systems.

What Are Dental Handpieces

Dental handpieces represent precision-engineered instruments that convert compressed air or electric power into controlled rotational motion, making them indispensable for cutting, polishing, and shaping teeth during dental procedures. These sophisticated tools serve as the primary interface between the practitioner and the patient, delivering the mechanical force necessary for tissue modification while maintaining the delicate control required for successful treatment outcomes.

The fundamental design of dental handpieces centers around their ability to efficiently transfer power from air motors or electric motors to specialised cutting instruments called burs. This power transmission occurs through carefully engineered mechanisms that maintain consistent speed and torque while providing adequate cooling and debris removal through integrated spray systems.

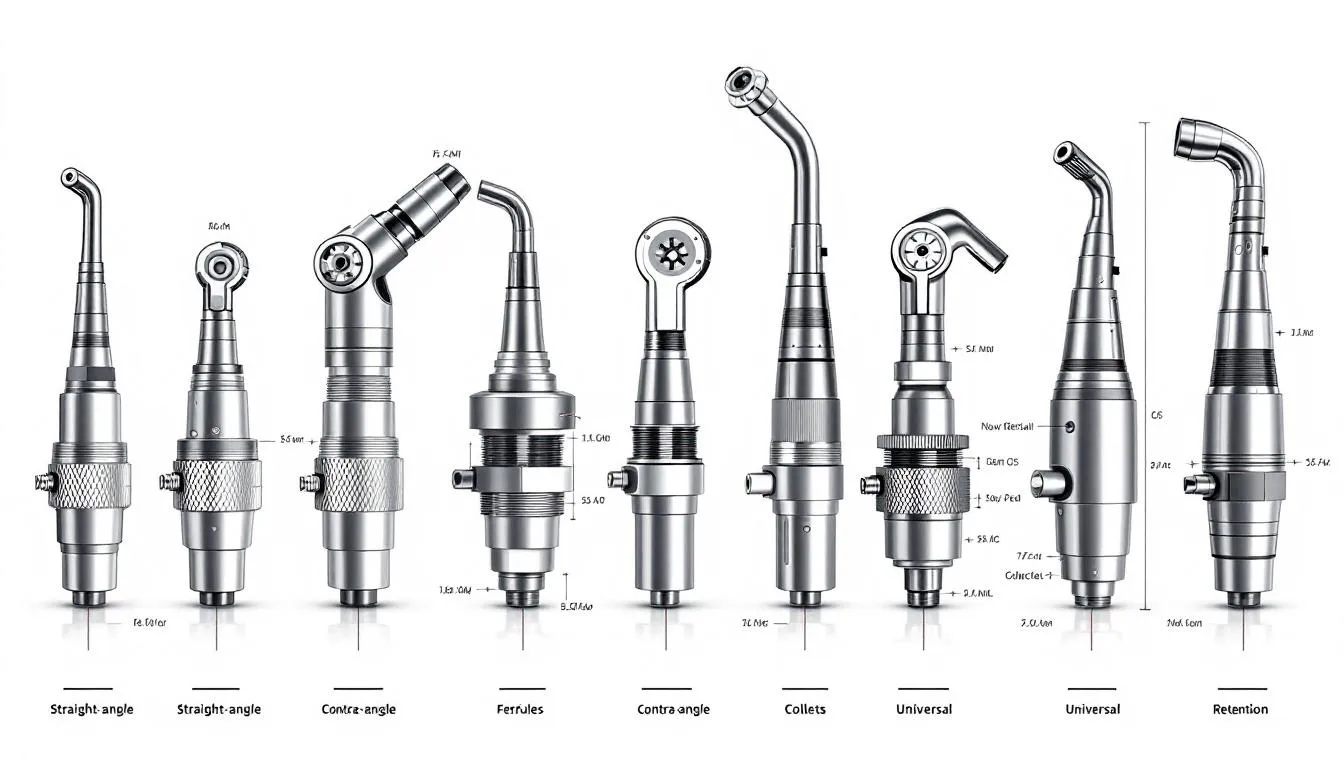

Modern handpieces are available in two primary configurations: high-speed turbine systems operating at speeds between 300,000-450,000 RPM, and low-speed contra angle attachments that typically function at 160,000-200,000 RPM when paired with speed-increasing mechanisms. Each configuration serves specific clinical applications, with high speed handpieces excelling in hard tissue removal and cavity preparation, while low-speed systems provide superior control for finishing and polishing procedures.

The key components that enable handpiece functionality include the turbine rotor system, precision bearings that ensure smooth rotation, comprehensive spray systems for cooling and irrigation, and coupling mechanisms that connect the handpiece to the dental unit’s air and water supply. These components work in harmony to deliver consistent performance while maintaining the reliability demanded in clinical environments.

Types of Dental Handpieces

Understanding the distinct categories of dental handpieces is essential for making informed equipment decisions that align with your practise’s clinical requirements. Each type offers specific advantages designed to optimise particular procedures, and selecting the appropriate combination can significantly impact both treatment efficiency and patient comfort.

|

Handpiece Type |

Speed Range |

Power Source |

Primary Applications |

|---|---|---|---|

|

High-Speed Turbines |

300,000-450,000 RPM |

Compressed Air |

Cavity preparation, crown preparation, enamel removal |

|

Speed-Increasing Contra-Angles |

160,000-200,000 RPM |

Electric Motors |

Precision cutting, endodontic access |

|

1:1 Direct Drive |

40,000 RPM |

Electric Motors |

Polishing, finishing |

|

Straight Handpieces |

5,000-40,000 RPM |

Air/Electric |

Laboratory work, direct access |

|

Surgical Handpieces |

800-50,000 RPM |

Electric Motors |

Implant placement, bone preparation |

High-Speed Handpieces (Turbines)

High-speed turbine handpieces operate at remarkable speeds between 300,000-450,000 RPM using compressed air pressure typically ranging from 3.0 to 4.2 bar. These powerful instruments excel in procedures requiring rapid hard tissue removal, making them the primary choice for cavity preparation, crown preparation, and enamel removal tasks that demand both speed and precision.

The efficiency of high-speed handpieces stems from their turbine-driven design, which converts compressed air into rotational motion through carefully engineered rotor assemblies. This air-driven system provides the advantage of instant speed control and eliminates the heat buildup commonly associated with electric motors during extended use.

Modern high-speed handpieces are available with integrated LED lighting systems, commonly referred to as optic models, or without lighting in non-optic configurations. The optic versions significantly enhance visibility during procedures, particularly in posterior regions where natural lighting is limited. Popular models include the NSK Ti-Max Z990L, which features titanium construction for reduced weight, the KaVo EXPERT series known for exceptional reliability, and the W&H Synea Fusion that combines power with ergonomic design.

The turbine mechanism within these handpieces consists of precision-balanced rotors supported by high-quality bearings that ensure smooth operation and extended service life. Regular maintenance of these components is crucial for maintaining optimal performance and preventing unexpected failures during critical procedures.

Low-Speed Handpieces

Low-speed handpiece systems encompass several distinct categories, each engineered for specific clinical applications that require enhanced control and torque rather than maximum cutting speed. These versatile instruments form the backbone of finishing procedures, polishing tasks, and specialised surgical applications.

Speed-increasing contra angles represent the most sophisticated category within low-speed systems, operating at 160,000-200,000 RPM when paired with compatible electric micromotors. These instruments require electric motors capable of supporting increased speed ratios and are essential for procedures demanding higher cutting efficiency than standard handpieces can provide, including endodontic access and precision cutting procedures.

The 1:1 direct drive contra angles operate at approximately 40,000 RPM and serve as the workhorses for polishing and finishing applications. These instruments connect directly to electric micromotors without speed modification, providing excellent torque control for detailed work on restorative materials and final surface preparations.

Straight handpieces offer direct access capabilities and are particularly valuable for laboratory work and extraoral procedures. Their linear design eliminates angular restrictions, making them ideal for precise work on prosthetic appliances and orthodontic devices where unobstructed access is essential.

Key Features and Technologies

The evolution of dental handpiece technology has introduced sophisticated features that significantly enhance clinical outcomes while improving practitioner comfort and efficiency. Understanding these technological advances is crucial for making informed equipment investments that will serve your practise effectively for years to come.

Optic Systems and LED Technology

Integrated LED fiber-optic lighting represents one of the most significant advances in handpiece technology, providing enhanced visibility during procedures that directly translates to improved precision and reduced eye strain. Modern LED systems offer superior illumination compared to traditional halogen systems while consuming less power and generating minimal heat.

The benefits of optic handpieces extend beyond simple illumination, contributing to improved precision through better visualization of the working area, reduced eye strain during extended procedures, and enhanced patient comfort through reduced chair time. These systems are compatible with major dental unit manufacturers including Bien Air, W&H, NSK, and KaVo systems, ensuring broad integration possibilities.

LED technology has largely replaced older halogen systems due to its longer lifespan, cooler operation, and more consistent light output. The integration of these lighting systems into the handpiece head eliminates shadows that can obscure the working area, particularly in posterior regions where access and visibility are naturally limited.

Modern optic systems also feature improved light transmission through advanced fiber-optic bundles that maintain illumination intensity throughout the handpiece’s service life. This consistency ensures that practitioners can rely on optimal visibility regardless of the handpiece’s age or usage level.

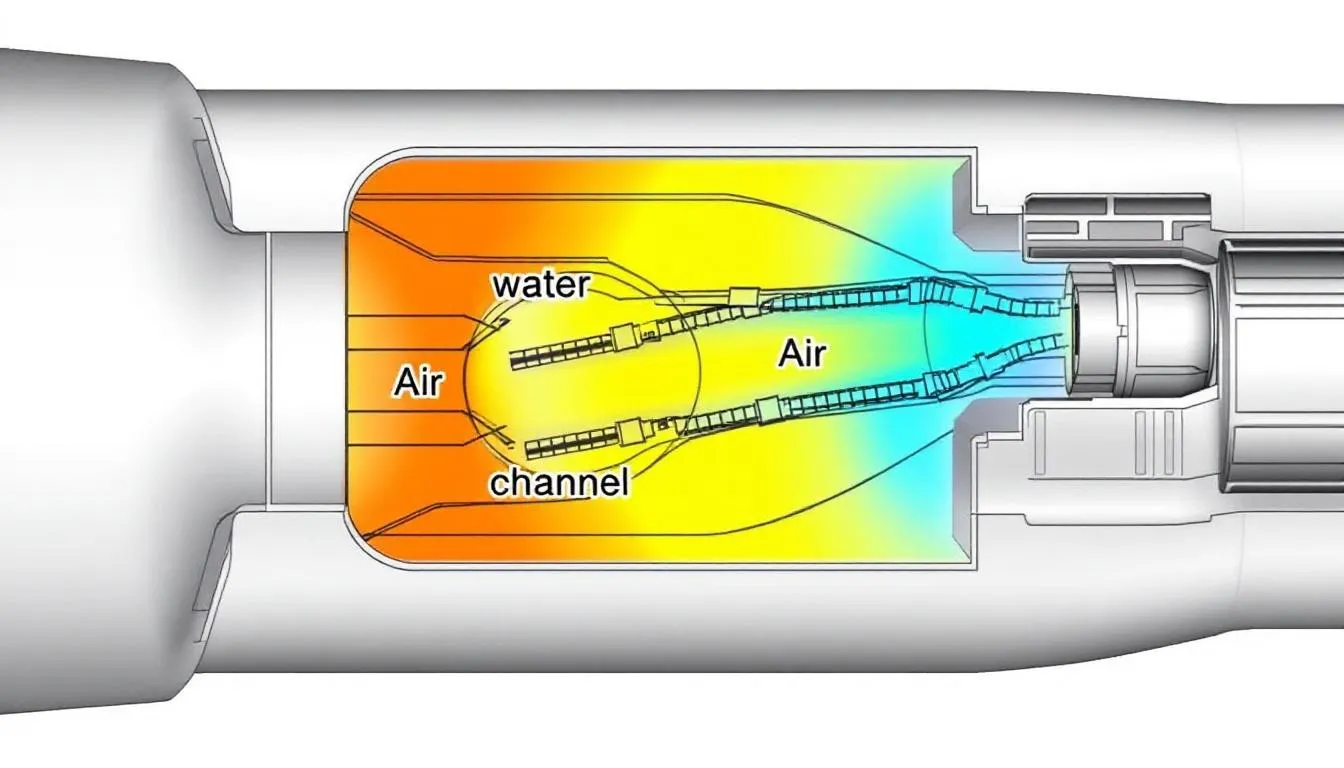

Spray and Cooling Systems

Effective cooling and irrigation systems are fundamental to successful handpiece operation, preventing thermal damage to dental tissues while maintaining optimal cutting conditions. Modern handpieces incorporate sophisticated spray patterns and cooling technologies that significantly enhance both performance and patient comfort.

The standard 4-hole spray pattern provides optimal air and water cooling by directing multiple streams precisely to the cutting area. This configuration ensures adequate heat dissipation while maintaining clear visibility through effective debris removal. Advanced systems feature triple water spray technology that enhances temperature control during aggressive cutting procedures.

External irrigation connections accommodate surgical procedures requiring saline solutions or other specialised irrigation fluids. These connections allow practitioners to customize the irrigation medium based on specific procedural requirements, particularly valuable during implant placement and oral surgery procedures.

Clean Head System technology represents a significant advancement in handpiece hygiene and maintenance. This system facilitates improved cleaning between patients while simplifying the maintenance procedures required to keep handpieces operating at peak efficiency. The technology also extends bearing life by preventing contaminant buildup in critical internal components.

Popular Handpiece Series and Models

Selecting the appropriate handpiece series requires careful consideration of your practise’s specific needs, budget constraints, and long-term equipment strategies. Leading manufacturers offer diverse product lines designed to meet varying clinical requirements while providing different levels of features and warranty coverage.

NSK Ti-Max Series

The NSK Ti-Max series represents the pinnacle of lightweight handpiece design, featuring titanium construction that significantly reduces hand fatigue during extended procedures. This advanced material selection provides exceptional strength-to-weight ratios while maintaining the durability required for intensive clinical use.

The Ti-Max Z990L and Z890L models feature high power output capabilities combined with quick-stop functionality that enhances procedural efficiency and safety. These handpieces incorporate 100-degree angled heads that improve access to posterior teeth while maintaining comfortable hand positioning throughout treatment.

All Ti-Max series handpieces include comprehensive 3-year warranty coverage and demonstrate compatibility with air pressure systems operating between 3.0-4.2 bar. This broad compatibility range ensures optimal performance across different dental unit configurations while maintaining consistent cutting efficiency.

The titanium construction offers additional benefits beyond weight reduction, including enhanced corrosion resistance and improved autoclave compatibility. These characteristics contribute to extended service life and reduced maintenance requirements compared to traditional stainless steel alternatives.

S-Max and Pana-Max2 Series

The S-Max series features robust stainless steel construction offering exceptional durability backed by comprehensive 2-year warranty coverage. These handpieces provide an excellent balance of performance and value for practises seeking reliable equipment without premium material costs.

S-Max models incorporate superior power output capabilities combined with efficient 4-hole spray systems that ensure optimal cooling and debris removal during procedures. The stainless steel construction provides excellent autoclave compatibility while maintaining dimensional stability throughout extended service life.

The Pana-Max2 series offers unique direct hose connection capabilities that eliminate traditional coupling requirements. This design simplifies handpiece setup while reducing potential failure points that can compromise reliability during critical procedures.

Both series feature DIY cartridge replacement systems that allow practise staff to perform routine maintenance procedures without requiring specialised service calls. This capability reduces downtime while providing cost-effective maintenance solutions that keep handpieces operating at peak efficiency.

Specialised Handpiece Applications

Modern dental practises increasingly require specialised handpieces designed for specific procedures that demand unique performance characteristics. These specialised instruments expand treatment capabilities while ensuring optimal outcomes in demanding clinical applications.

Surgical and Implant Handpieces

Surgical handpieces featuring 20:1 speed reduction ratios are specifically engineered for implant placement procedures that require precise control and high torque output. These instruments operate at significantly reduced speeds compared to standard handpieces, typically ranging from 800 to 50,000 RPM depending on the specific application.

External spigot connections accommodate saline irrigation during oral surgery procedures, providing the specialised cooling and debris removal required for bone preparation and implant site development. These connections ensure compatibility with sterile irrigation solutions while maintaining the aseptic conditions essential for successful surgical outcomes.

Compatibility with advanced motor systems including Surgic Pro, Surgic Pro2, and Surgic XT platforms ensures that these handpieces integrate seamlessly with existing surgical equipment. These motor systems provide the enhanced torque control necessary for precise bone preparation and implant site development procedures.

The enhanced torque characteristics of surgical handpieces make them indispensable for procedures requiring controlled material removal in dense bone or challenging anatomical locations. This capability ensures predictable outcomes while minimizing the risk of thermal damage to surrounding tissues.

Speed-Increasing Contra-Angles

Speed-increasing contra angles require electric micromotors specifically designed to support increased rotational speeds while maintaining adequate torque for effective cutting. These sophisticated instruments fill the performance gap between traditional low-speed handpieces and high-speed turbines.

The specialised electric motor requirements ensure that these handpieces receive adequate power to maintain consistent cutting efficiency throughout demanding procedures. Only specific electric motor systems support the increased speed ratios required for optimal performance, making motor compatibility a critical selection criterion.

Applications for speed-increasing contra angles include endodontic access procedures where precision and control are paramount, and specialised cutting procedures that require higher speeds than traditional low-speed handpieces can provide. These instruments excel in situations demanding the control of low-speed systems combined with enhanced cutting efficiency.

The versatility of speed-increasing contra angles makes them valuable additions to practises performing diverse procedures requiring varying speed and torque characteristics. Their ability to bridge the performance gap between high-speed and traditional low-speed systems expands treatment possibilities while maintaining procedural efficiency.

Maintenance and Care Guidelines

Proper maintenance protocols are essential for ensuring reliable handpiece performance while maximizing equipment lifespan and minimizing unexpected failures. Implementing comprehensive maintenance procedures protects your equipment investment while ensuring consistent clinical performance.

Regular cleaning protocols should be implemented immediately following each patient use, beginning with thorough external cleaning using appropriate disinfectants and progressing through complete internal flushing to remove debris and contaminants. These procedures prevent buildup that can compromise performance or create infection control risks.

Lubrication schedules must be followed precisely according to manufacturer specifications, typically requiring daily lubrication for heavily used handpieces and weekly maintenance for instruments with lighter usage patterns. Proper lubrication prevents bearing wear while ensuring smooth operation throughout the handpiece’s service life.

Bearing replacement indicators include increased noise levels during operation, reduced cutting efficiency, or visible wobble in the bur during rotation. Recognizing these early warning signs allows for proactive maintenance that prevents complete handpiece failure during critical procedures.

Sterilization guidelines must accommodate autoclave cycles at 134°C while following manufacturer-specified protocols for preparation and post-sterilization handling. Proper sterilization techniques ensure infection control compliance while preventing damage to sensitive internal components.

Common troubleshooting procedures address issues including reduced speed, which often indicates insufficient air pressure or internal contamination, spray problems that may result from blocked water lines or damaged seals, and unusual noise that typically signals bearing wear or internal damage requiring professional service.

Compatibility and Selection Criteria

Selecting appropriate handpieces requires careful evaluation of multiple factors including air pressure requirements, coupling compatibility, motor specifications, and budget considerations. Understanding these criteria ensures that your equipment investments align with both current needs and future practise growth.

Air pressure requirements typically range from 3.0 to 4.2 bar for optimal handpiece performance, with specific models requiring particular pressure ranges for peak efficiency. Ensuring that your dental unit can provide adequate air pressure prevents performance issues while protecting handpiece components from damage.

Coupling compatibility with major dental unit manufacturers is essential for seamless integration with existing equipment. Most handpieces are designed to work with standard coupling systems, but verifying compatibility prevents costly adaptation requirements or performance compromises.

Electric motor requirements for low-speed handpieces include specific torque specifications and power output capabilities that must match handpiece demands. Understanding these requirements ensures that your motor and handpiece combinations deliver optimal performance across all intended applications.

Budget considerations should evaluate both initial purchase costs and long-term ownership expenses including maintenance, replacement parts, and warranty coverage. Titanium construction typically commands premium pricing but offers reduced weight and enhanced durability, while stainless steel options provide excellent value for practises with budget constraints.

The selection process should also consider your practise’s specific procedural mix, with high-volume restorative practises benefiting from premium high-speed handpieces, while general practises may find more value in versatile low-speed systems with multiple attachments. Specialty practises should prioritize handpieces designed for their specific applications, such as surgical or endodontic procedures.

Warranty coverage and service support availability represent critical factors in handpiece selection, particularly for practises in remote locations where service access may be limited. Comprehensive warranty coverage protects your investment while ensuring that equipment problems don’t disrupt patient care.

Training requirements and staff familiarity should also influence selection decisions, as introducing new handpiece systems may require additional training time and temporary productivity reductions. Selecting systems similar to existing equipment can minimize transition challenges while maintaining clinical efficiency.

The decision between air-driven and electric handpieces depends on your practise’s specific requirements, with air systems offering simplicity and instant speed control, while electric systems provide consistent torque and quieter operation. Each technology offers distinct advantages that should align with your clinical preferences and patient demographics.

Long-term equipment strategies should consider technological advancement trends and manufacturer support commitments. Investing in handpieces from manufacturers with strong research and development programs ensures access to ongoing innovations and extended product support throughout the equipment’s service life.

Modern dental handpieces represent sophisticated precision instruments that significantly impact both clinical outcomes and practise efficiency. By understanding the technical specifications, clinical applications, and selection criteria outlined in this guide, you can make informed decisions that enhance your practise’s capabilities while providing exceptional patient care.

The investment in quality handpieces pays dividends through improved procedural efficiency, enhanced patient comfort, and reduced maintenance requirements. Whether you’re upgrading existing equipment or establishing new practise capabilities, selecting appropriate handpieces based on your specific needs ensures that these essential instruments will serve your practise effectively for years to come.

Remember that proper maintenance and care are just as important as initial selection in maximizing your handpiece investment. Implementing comprehensive maintenance protocols protects your equipment while ensuring consistent performance that meets the demanding requirements of modern dental practise.